Professional servo potestate universalis testis materiae testis

- Product Description

Computer Automatic HYDRAULICUS Universalis Testing Machina

1.Matters opus operam

Placere legit hoc manual diligenter ante usura is apparatu, et custodiat eam pro futuro referat proposita

In installation environment requisita

① environment temperatus X ℃ ~ XXXV ℃

② relative humiditas non plus quam LXXX%

③ non vibrationis, non corrosio, nec fortis electro intercessiones environment

④ in gradu debet esse non plus quam 0.2mm / 1000mm

⑤ non sit circa 0.7m spatium, apparatu debet esse firmiter grounding.

Powered

Hoc apparatu usus 380V tres-tempus quattuor filum (praeter aliam tips) alterna current (n), intentione stabilitatem, non excedent ± X% of rated intentione, non excedat de basibus non excedat 10a.

HYDRAULICUS Oil

Et apparatu adoptat vexillum hydrau oleum ut opus liquor: cum locus temperatus est altior quam XXV ℃, usura no.68 anti-gerunt hydraulico oleum. Cum locus temperatus est infra XXV ℃, usura no.46 anti-gerunt hydraulicis oleum.

In hieme, cum locus temperatus nimis humilis, postquam conversus in apparatus placere preheating apparatu (satus oleum sentinam motricium) ad X minuta. Cum crebris usura, hydraulicis oleum debet reponi dimidium annus, utrum cibus cisternina et filter debet purgandum vel non placuit pollutio.

Hoc apparatu non utor engine oleum, gasoline vel oleum pro loco. Defectum de Hydraulica component propter improprium oleum, non includitur in scope warantia.

De subitis subsisto

In casu de an emergency in installation, operatio, ut solenoid valvulae potest dimittere, abnormes operationem motricium, quod potest causat damnum ad machina vel injuria.

Praecisione

Equipment est exacte calibrated priusquam relinquens fabrica, ne adjust calibration parametri. Mensurae errorem crescit propter alienum temperatio ad calibration parametri, non includitur in scope warantum. Vos can contactus cum loci qualitas vigilantia Department pro Calibration secundum apparatu vestigium accuracy genus.

Maximum Force

Determine the measuring range of equipment according to the equipment label, measuring range is adjusted in factory, do not alter the range parameter, adjustment of the range parameters could result in equipment output force is so large that causes damage to the mechanical parts or output force is so small that can not reach the setting value, the damage of mechanical components due to unauthorized adjustment for range parameters , will not be included in the scope of warranty.

2.Geneeral introductio

Waw series Electro-Hydrau servo universalis testis machina

Waw Series Electro-Hydrau servo universalis testis machina fundatur in GB / T16826-2008 "Electro-Hydraulicorum Servo universalis testis Apparatus - T228.1-2010 Testing Machina, quae developed manufactured based on that. This series of testing machine is loaded with hydraulic , using the electro-hydraulic servo control technology for tensile testing, compress testing, bend testing,shear testing of metal and non-metallic materials,display a variety of curves,including stress, deformation, displacement and other closed loop control mode, can be arbitrarily switched in the experiment. It records and stores data automatically. It MB,

ISO, ASTM, Din, Jis et aliis signis.

Et features of Waw series Electro-Hydrau servo universalis testis apparatus (Type B):

① In test adoptat microcomputer automatic mode, cum munera accentus rate, iactabantur rate, accentus sustentacionem et iactabantur sustentationem;

② capere summus praecisione centrum, et-locutus est sensorem ad modum vis;

③ exercitum, quae adoptat quatuor columnae et duplex Cochleas test spatialis structuram

④ communicate cum PC per summus celeritas Aer communicationis interface;

⑤ administrare test notitia per vexillum database;

⑥ altum vires, princeps lenta et pulcherrima tutela rete salus praesidio

4.Installation et Commissioning

Para installation Tools

Reprehendo accessiones attachiatus ad apparatu iuxta sarcina album et reprehendo an accessiones completum parare screwdriver, Populus Novifacta et paro interiore sex angulus clavis

Fige principalis engine

Fige apparatu secundum fixum parametri fundamentum cum ad fundamentum drawing (videatur in parametri et instructiones fundamenta in Appendice huius manual ad details) PRAETORQUENTIA et ad vitare damnum et fecit incommodo in motum apparatus in futurum. Nexum esse propinqua, et codex in signing washer.

Et oleum circuitu connexionem

Fill the right amount of hydraulic oil according to the mark on the oil tank (wait at least 3 hours before officially use after filling the hydraulic oil , to facilitate the bubble discharge in the hydraulic oil by itself), after filling the hydraulic oil connect the main engine and the control cabinet with hose in accordance with the sign (hydraulic jaw type requires jaw pipeline installation),when installing the pipeline,one gasket must be Posuit inter Pipeline et Splice et cingulo in iuncturam per clavis, ut ostensum est unscrewed oleum obturaculum de caligarum sis ut tutus, ut vitare damnum et fecit incommodum machina in futurum. Cum movere apparatu placere destruam pipelines signare oleum obturaculum propinqua.

Electrica nexu

Tolle totam paro data lineas secundum notitia linea correspondentes interface in potestate arca. Quaeso coniungere virtute spinalis in stricte secundum coniuncta label. NULT filum (linea IV) De tribus-tempus quattuor filum potentia linea est stricte prohibetur iniuriam nexu.

Aperi computatrum sarcina, install computatrum (hoc gradum non solum idoneam ad exempla quae continet computatrum); Deinde install unus finis Rs-CCXXXII communicationis linea in controller, in altera finis install in computer. Placere non reponere computatrum una cum apparatu. (Tips: Hoc gradum non requiritur ad Industrial Computer Type)

Open the printer package and install the printer according to the installation instructions attached to the printer (this step is only applicable to models containing external printer);After the printer is installed and connected to the computer, place it in a convenient location (the printer driver is saved on the local disk of the computer and needs to be installed by yourself) .

Primum operationem et commissionis

After electrical installation finished, switch on the power of the equipment, turn on the equipment.Use the control panel on the control cabinet or control box ,to rise the middle girder some distance (if the beam falls,you should immediately stop the operation and adjust the power phase sequence), then in accordance with the manual, operate the equipment with no-load, durning the rising of the worktable (can't exceed the maximum stroke),please observe if there is abnormal Phaenomenon, si dose, vos uninstall et prohibere reprehendo, remedium tribulationis; Si non unloading donec Piston ad normalis positio committerat terminos.

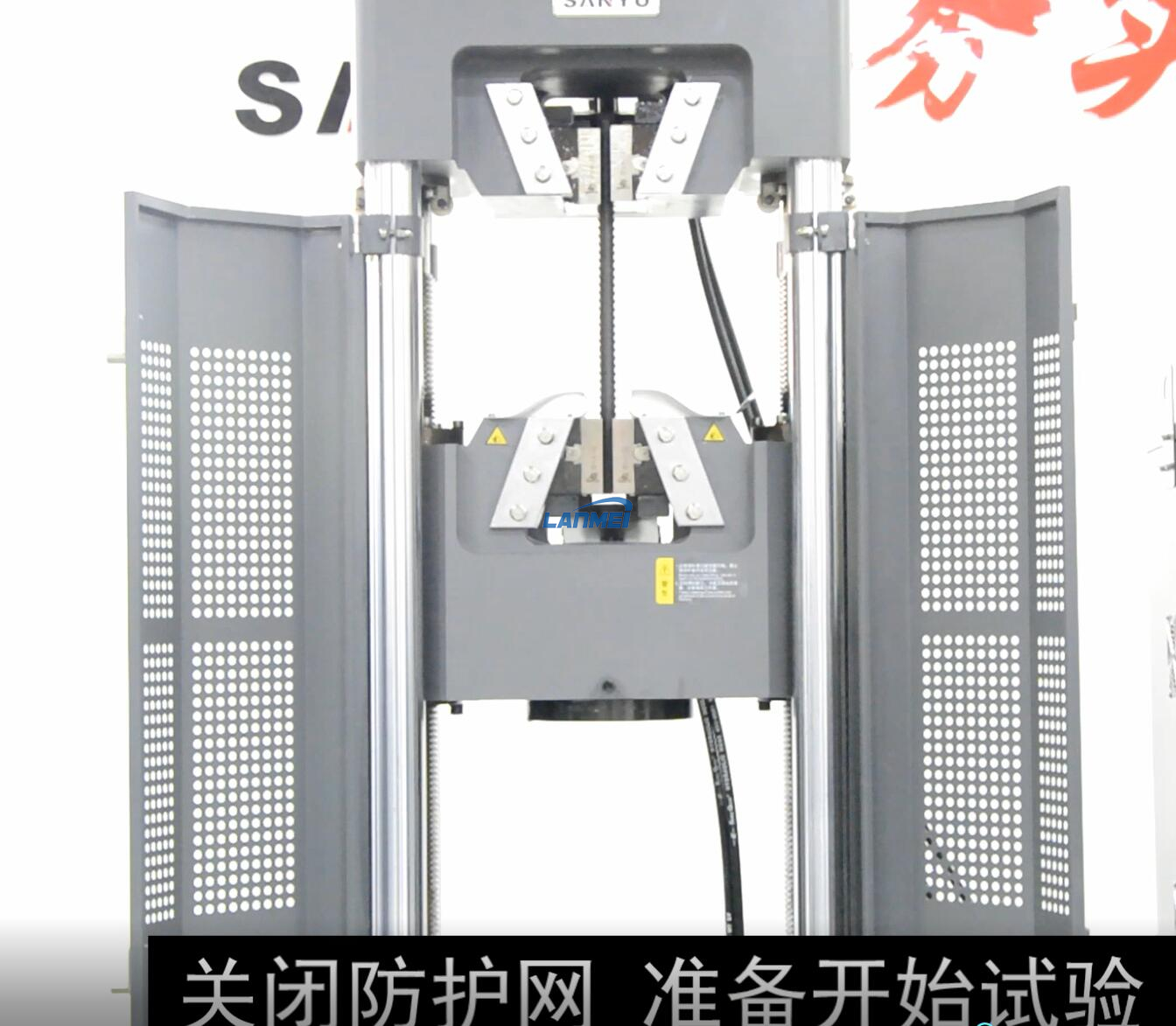

Apparatu diagram